-

Phone: +86 18858673523

-

E-mail: avaxu@cnfeltingneedle.com

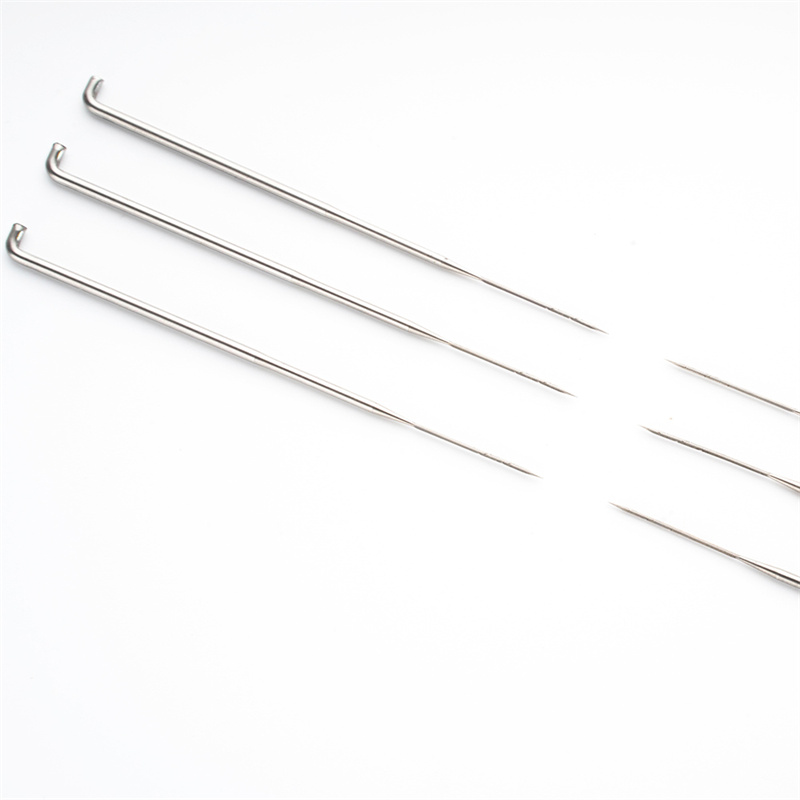

Wholesale Star Felting Needles For Papermaking Carpet Custom Stainless Steel Needles

Product Description

Quick Details

Product name: Felting needles

Warranty: 1.5 years Applicable

Brand Name: YUXING

Use: NEEDLE LOOM

Type: NEEDLE BOARD

Production capacity: 600 million

Condition: New

Raw material: HIGH CARBON STEEL

Place of Origin: Zhejiang, China Brand

Application: For Needle nonwoven fabric

Packing: Well packed from water and damage

Packaging & Delivery

MOQ: 10000pcs

Selling Units: Multiple of 10000

Package size per batch: 32X22X10 cm

Gross weight per batch: 12.00 kg

Package Type: 500pcs into 1 plasitc box, then 10000pcs again into 1 carton box

Picture Example:

Lead Time:

|

Quantity(Pieces) |

1 - 500000 |

>500000 |

|

Est. Time(days) |

10 |

To be negotiated |

Products Show

Product Description

Gauges and diameters of Felting Needles

|

Gauge |

Shank (mm) |

Intermediate Section (mm) |

Working part Triangular blade beight

(mm) |

|

9 |

3.56 |

||

|

10 |

3.25 |

||

|

12 |

2.67 |

||

|

13 |

2.35 |

2.50 |

|

|

14 |

2.03 |

2.05 |

|

|

15 |

1.83 |

1.75 |

1.95 |

|

16 |

1.63 |

1.55 |

1.65 |

|

17 |

1.37 |

1.35 |

1.45 |

|

18 |

1.21 |

1.20 |

1.30 |

|

19 |

1.15 |

||

|

20 |

0.90 |

1.00 |

|

|

22 |

0.95 |

||

|

23 |

0.92 |

||

|

25 |

0.80 |

0.90 |

|

|

26 |

0.85 |

||

|

28 |

0.80 |

||

|

30 |

0.75 |

||

|

32 |

0.65 |

0.70 |

|

|

34 |

0.65 |

||

|

36 |

0.60 |

||

|

38 |

0.55 |

||

|

40 |

0.50 |

||

|

42 |

0.45 |

||

|

43 |

0.40 |

||

|

46 |

0.35 |

||

|

The diameter of different parts of needle is indicated by gauge. The smaller gauge meams the larger diameter. When in the working part, the cross-section height is indicated by working part gauge. The cross-section height of conical working part is measured on the position of 5mm from needle point. The other cross-section shape is measured by their height. |

|||

|

Detailed parameters of the felting needle

|

||

|

Product name |

Star fleting Needles |

|

|

|

||

|

texture |

high-carbon steel |

|

|

colour |

bright nickel white |

|

|

Barb spacing |

regular spacing |

|

|

medium spacing |

|

|

|

close spacing |

|

|

|

frequent spacing |

|

|

|

single spacing |

|

|

|

Barb Styles |

Type F (Good penetration and hair amount, generally used as pre-piercing) |

|

|

Type G Less damage to fiber |

|

|

|

Type B Less damage to fiber |

|

|

|

Type GB Morewear-resistant during use |

|

|

|

Type L On the basis of the B type, the hook teeth are more rounded |

|

|

|

Type K(Open style needle) (Can make the hook spines with better hair quantity) |

|

|

|

4.0 inch |

|

|

|

3.5 inch |

|

|

|

3.0 inch |

|

|

| The above-provided sizes are standard sizes. For some particular purposes, non-standard sizes are also available. | ||

|

Standard working part lengths on felting needles |

30mm |

|

|

24mm |

|

|

| The above-provided sizes are standard sizes. For some particular purposes, non-standard sizes are also available. | ||

Application field

A nonwoven is a material made of fibers bonded together by high temperature, chemical or mechanical means. Among them, mechanical bonding needs to be performed using needles. During mechanical bonding, the fibers are fed through barbed needles and intertwined with the fabric. This entanglement process increases the friction between the fibers, thereby enhancing the bonding effect of the nonwoven. A needle machine is a special piece of equipment in which a large number of needles are embedded in the dial. The needles pass through the nonwoven in a prescribed direction, intertwining the fibers together. This needle making machine is mainly used to produce geotextiles, filter cloths, filter bags, artificial leather, disposable carpets, automotive interiors, handmade wool, pure cotton, bra cotton and other products with surface requirements. To sum up, the mechanical needle making machine makes the fibers of the nonwoven fabric bond to each other through the conveying and winding of the needle, which improves the surface compactness and strength of the nonwoven fabric, and is suitable for a wide range of application.

Automotive Interior

Soundproof Cotton

Artificial Leather

Filter Bag

Linoleum Machine

Cloth Geotextile

Handicrafts

Woolen Blanket

Wool Felt

Features

* The working area is like an equilateral four-pointed star

* The working area should be parallel from the tip to the tapering cone

* The barbs on all edges are of the same size

* Most common number of barbs: 1 or 2 barbs per edge

Advantages

*The hooks and thorns are distributed on the four edges, and the acupuncture efficiency is higher

*More uniform MD/CD tensile strength ratio (longitudinal/horizontal)

Our factory

Contact Us

If you have another question, pls feel free to contact us as below:

Phone

+86 18858673523

+86 15988982293